[FULL] GMP Factory Information and Standards

Surely we are familiar with the phrase "GMP standard" on the packaging of functional foods and medicines. In fact, only GMP factories (factory meeting GMP standards) can produce GMP standard products. Also according to the regulations of the Ministry of Health, pharmaceutical factories MUST have GMP certification.

So what is GMP standard? What kind of factories will meet GMP standard? Read the article below to find the answer!

I. What is a GMP factory? What is GMP standard?

1. What is GMP?

GMP stands for Good Manufacturing Practices.

GMP refers to the Good Manufacturing Practices regulations issued by the United States Food and Drug Administration. Good Manufacturing Practices (GMP) is a system that ensures that products are consistently produced and controlled according to quality standards. (Reference source: who.int ).

The purpose of developing GMP standards for factories: Minimize risks associated with any pharmaceutical manufacturing activity that cannot be eliminated through final product testing.

WHO GMP standards

Many countries have developed their own GMP requirements based on WHO GMP. Other countries have harmonised their requirements, for example within the Association of Southeast Asian Nations (ASEAN), in the European Union and through the Pharmaceutical Inspection Convention.

2. Which industries are currently applying GMP factory standards?

There are 4 industries currently on the “special list” of the Ministry of Health. Product lines in these industries are required to be created from GMP-certified factories, including:

- Pharmaceutical factories

- Equipment manufacturing plant

- Food factory

- Cosmetics factory

The common point of these 4 product groups: They are all related to human health. For this reason, GMP factory standards are more concerned and tightened than ever.

GMP factory standards are very important in pharmaceutical production.

3. What standards must a factory meet to meet GMP standards?

GMP covers all aspects of manufacturing; from raw materials, premises and equipment to employee training and personal hygiene. Manufacturing facilities to receive GMP certification must meet the following requirements:

3.1. Must meet the requirements for human resources

“People” is one of the important factors in the list of GMP standards. For human resources, factories need to meet the following 2 requirements:

- Ensuring the health of workers

- Ensure staff training and education

Detailed explanation: Manufacturing plants must ensure that workers are in the best health during the production process. In addition, training courses must be held regularly to supplement employees' knowledge and skills.

3.2. GMP factories must meet documentation standards.

Specific requirements for documentation used in factories are as follows: Documents and procedures must be written and recorded and clearly presented according to GMP standards.

3.3. GMP has very high requirements for factories and equipment.

PRODUCTION AREA: Must be arranged separately and closed. Production area is sufficient to meet all activities. Floors and ceilings have no gaps and are waterproof. There is an insect and deodorizing system.

GENERAL REGULATIONS: The factory must ensure conditions of light, humidity, ventilation system, anti-insect system... There must be measures to minimize environmental contamination of products and raw materials that make up the products.

3.4. Strict GMP production process

The factory must have a clear and strictly followed inspection process. The production process will also be continuously monitored by the staff, helping to minimize problems related to product quality.

3.5. Meet product preservation standards

The storage area must be distributed with a large enough area, ensuring cleanliness, dryness, adequate light and temperature maintained at an appropriate level.

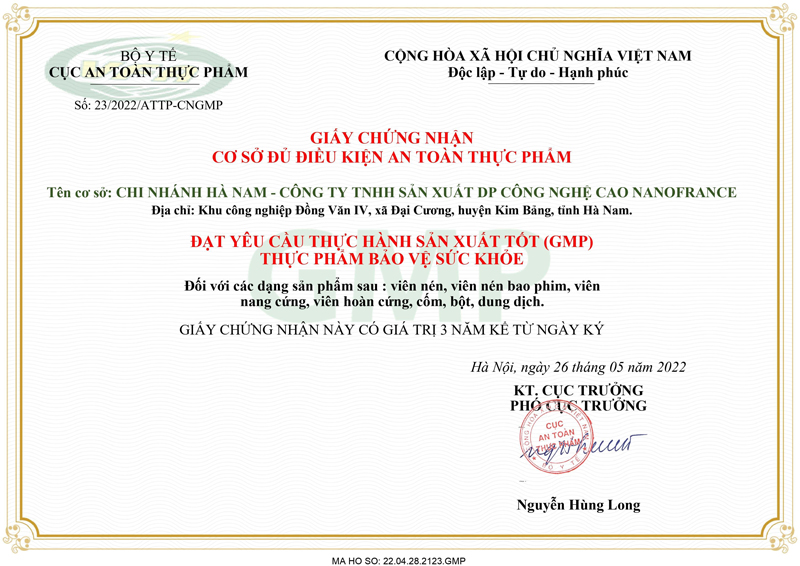

After fully meeting these standards, the factory will be granted a GMP certificate (as shown below):

GMP certificate after NanoFrance's re-evaluation

II. Why do distribution businesses need to cooperate with GMP-certified factories?

For distribution businesses that want to produce Functional Foods, Medical Equipment... why is it necessary to cooperate with a GMP standard processing factory?

1. Comply with the regulations of the Ministry of Health

Products that want to be distributed on the market must have sufficient documents and be licensed by the Ministry of Health. GMP standards are the most basic conditions. Therefore: Cooperating with a GMP standard manufacturing factory, creating GMP standard products is to comply with the regulations of the Ministry of Health.

Pharmaceutical factories must meet GMP standards - Regulations of the Ministry of Health

2. Ensure the production of high quality products

As mentioned above, GMP focuses on all the factors that go into creating a finished product. When all these factors are controlled and optimized, creating a high quality product is a given!

From the consumer’s perspective: Using high-quality products will bring stable health. This is also the basis for creating a sustainable product, bringing high revenue, and value to the community of distribution businesses.

3. Promote product export opportunities

Most countries will only accept the import and sale of drugs that have been manufactured to internationally recognized GMP standards. Governments seeking to promote their pharmaceutical exports can do so by mandating GMP for all pharmaceutical manufacturing operations and by training their inspectors in GMP requirements.

Do you want to produce dietary supplements, medical equipment, cosmetics at a GMP factory? Don't forget to contact NanoFrance! Call the hotline now 0986 859 777 for advice and support!