SOFT CAPSULES – WHAT YOU NEED TO KNOW!

Health is the most precious thing in human life, especially in the condition that harmful factors to health are increasingly common. Therefore, in addition to ensuring health by daily exercise and eating clean green foods, supplementing minerals and vitamins for the body with functional products is used more and more. Functional foods are prepared in many different forms to help consumers have many choices. Among them, soft capsules are widely used and bring quick results.

So what are soft capsules, what are the advantages and the soft capsule production process? Let's find out in this article!

What is a softgel?

Soft capsules are a form of medicine and functional food. The main structure of the capsule consists of 2 parts: the capsule shell and the active ingredient inside.

Capsules are like a soft mass, which contains active ingredients and excipients in a sealed shell with different shapes and sizes. Some of the main shapes of soft capsules are oval and oblong capsules.

The main ingredient of soft capsule shell is made of a mixture of gelatin, plasticizer, colorant, preservative. The medicine contained in soft capsule is usually in liquid, solution, suspension, emulsion form. The process of producing capsule shell takes place at the same time as the process of filling the medicine. This process takes place under strictly controlled conditions.

For soft capsules, when introduced into the body, the capsule shell will dissolve, releasing the active ingredients inside, helping to support disease treatment or improve the user's health.

Advantages of softgels

In addition to the benefits that the product brings, users are also interested in the dosage form of the product for convenience in use. So what are the advantages of soft capsules in use, let's find out!

Softgels overcome the fear of taking medicine

The fear of taking medicine greatly affects the choice of product formulation. Not only children and adults feel uncomfortable when taking medicine. For drugs prepared in the form of hard and bitter tablets, when entering the stomach, they will be difficult to digest. Therefore, to improve the fear of taking medicine, the pharmaceutical industry is increasingly developing, providing a solution to prepare soft capsules. Soft capsules are often small and quite soft, making them easy to swallow and digest when taken. This is considered one of the important benefits of soft capsules.

Dosage accuracy

During the manufacturing of this dosage form, all factors including machinery set up to process and produce quantities and ingredient details are precisely standardized.

The production process is guaranteed to take place continuously and simultaneously between the capsule shell and the active ingredient inside, helping to ensure accuracy and consistent dosage, thus bringing high efficiency when used.

Increase availability and efficiency

When using softgel products, the capsule shells are quickly digested, helping to release the active ingredients inside. Thereby providing nutrients to the body or supporting the treatment of diseases depending on each product.

Safe

All ingredients used to make softgels are primarily of natural, animal or cellular origin.

In addition, the soft capsule form is safer to use, especially for children because using hard capsules can cause choking.

When the product is packaged in soft capsules, it will help hide the taste of the active ingredients, protect the active ingredients from being affected by external factors such as temperature, humidity, light or incompatibility between ingredients in the product.

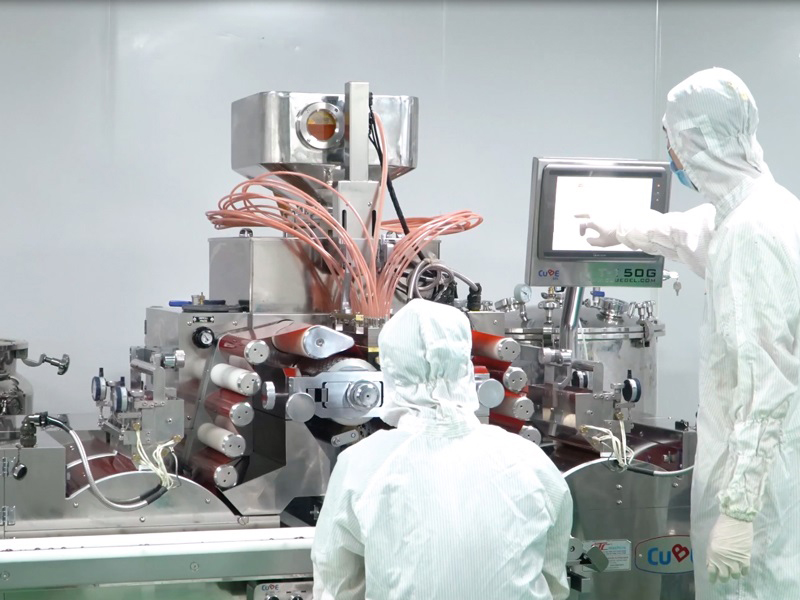

Softgel Capsule Manufacturing Process

To be able to produce soft gel, you must do it on modern production line and complete the following steps:

Step 1: Prepare product ingredients

Step 2: Prepare ingredients for the shell

Step 3: Weigh and measure raw materials for production.

Step 4: Mix all ingredients according to the standard formula and ratio curve.

Step 5: Divide the dosage of each capsule in detail.

Step 6: Proceed to create shell fluid

Step 7: Create a wet gel strip to prepare for capsule creation

Step 8: Create a capsule and make a brochure

Step 9: Dry the capsules in air via dryer

Step 10: Packing

Currently, NanoFrance does not process soft capsule products. In case you want to produce other dosage forms of dietary supplements such as: tablets, hard capsules, granules - powder, solutions..., do not forget to contact us!

NanoFrance High Technology DP Production Co., Ltd.

Factory 1: Dong Van IV Industrial Park, Dai Cuong, Kim Bang, Ha Nam

Factory 2: Do Quan, Quat Dong, Thuong Tin, Hanoi.

Office: BT5 – Lot B6, Ha Dinh Urban Area, Lane 214 Nguyen Xien, Thanh Xuan, Hanoi

Hotline: 0986 859 777 – 0971220888

Email: duocnanofrance@gmail.com

COME TO NANOFRANCE TO FEEL FROM THE SMALLEST THING!